Adjustable Speed Drives Lab — EE 4490

Director: Mehdi Farasat

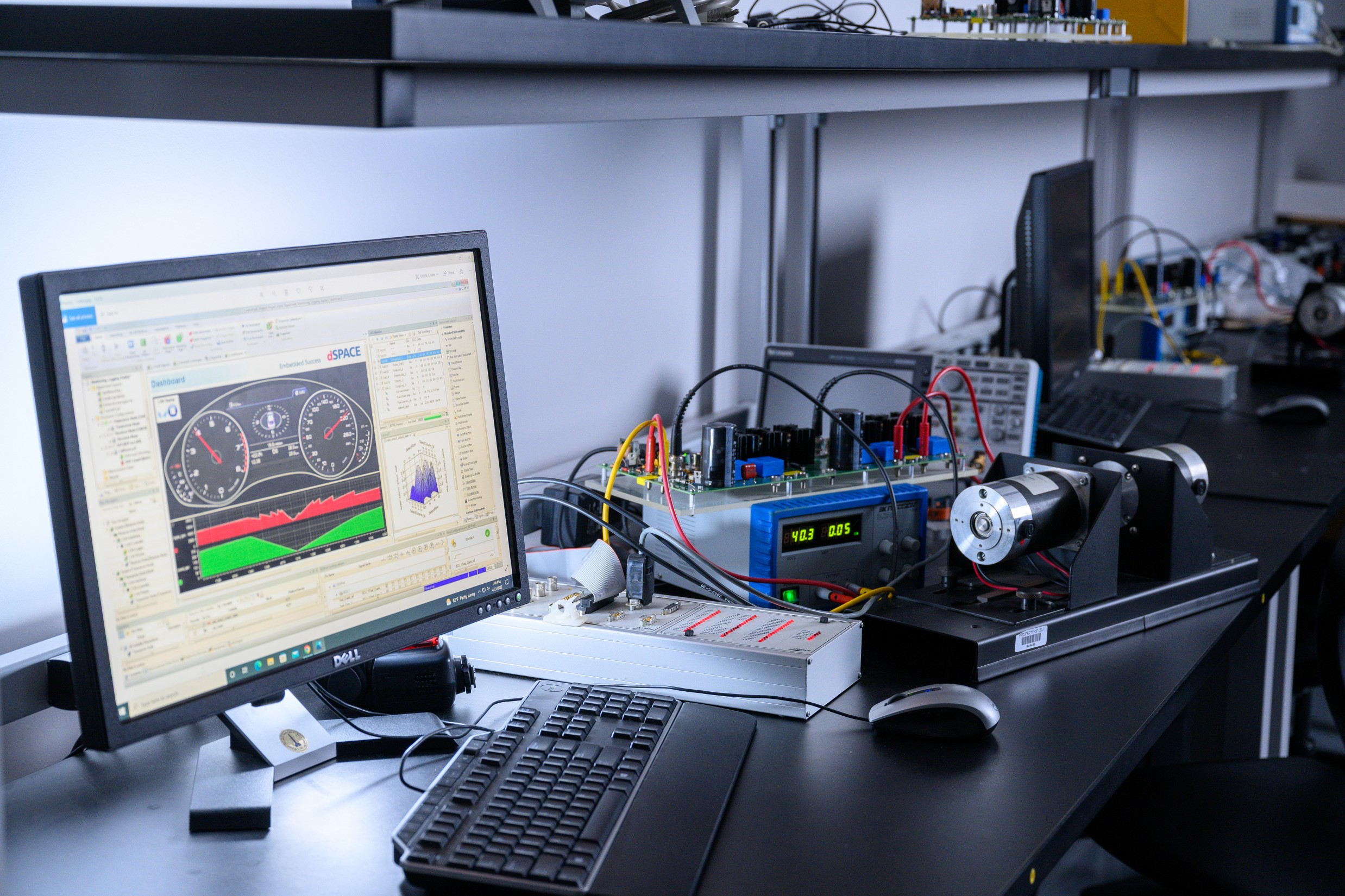

The Adjustable Speed Drives Laboratory provides students with hands-on experience in modeling, simulation, and real-time control of electric machines and drives. Using modern digital signal processor (DSP) platforms and power electronic converters, students learn how to implement, test, and analyze motor torque and control strategies for DC machines.

Major Equipment

- Motor coupling system with DC motors, induction motors, and permanent magnet AC motors (with encoders)

- Power Electronics Drive Board with dual 3-phase PWM inverters, sensors, and protection circuits, and dSPACE DS1104 R&D Controller Board with CP1104 I/O interface

- MATLAB/Simulink and ControlDesk software for real-time modeling, programming, and monitoring

Sponsors

Equipment sponsored by the National Science Foundation and LSU College of Engineering.

Lab Goals

In this lab, students design and test motor control strategies by combining simulation in MATLAB/Simulink with real-time implementation using DSP. Experiments cover fundamental drive concepts such as motor parameter identification, four-quadrant operation, and speed and torque control of DC motors. This practical experience bridges the gap between theoretical modeling and real-world electric drive applications.

Description

The Adjustable Speed Drives Laboratory introduces students in the study and application of modern electric motor control systems.

Beginning with the basics of mathematical modeling in Simulink, students progressively advance toward real-time implementation of controllers for DC machines using the dSPACE platform. The lab sequence guides students through key topics, including dynamic modeling of mechanical systems, switch-mode converter operation, motor parameter determination, closed-loop current and speed control, and four-quadrant drive operation.

Hands-on experiments involve configuring a motor coupling system, programming the DS1104 controller for generating PWM signals, and analyzing system response through ControlDesk interfaces. Students not only simulate drive systems but also implement them on real hardware, enabling them to observe the differences between modeled and experimental results.

By the end of the course, participants gain a thorough understanding of how power electronics, digital control, and motor dynamics integrate into functional adjustable speed drive systems used in industry.